MENPHIS PRESENTS WINDYE® AND BIOT® WITH ITS YOUNG RESEARCH AND DEVELOPMENT TEAM THAT ENHANCES THEIR CREATIVITY.

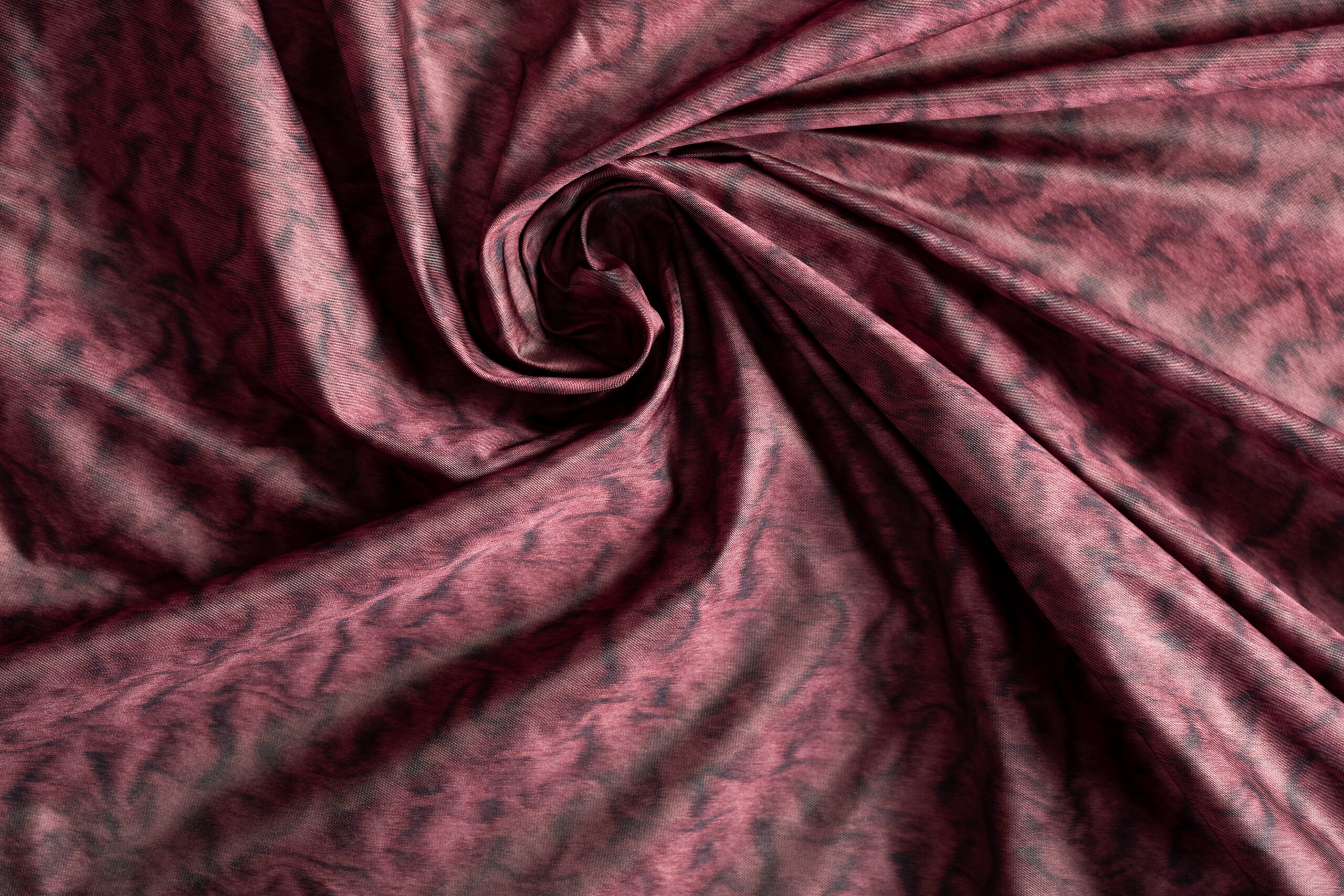

WINDYE, from winning dye or winning dyeing and printing, a new Menphis processing technique, the latest upgrade of a technology that never ceases to surprise for the quality and unique effects it is capable of producing, the result of a long path in innovation covering fifty years.

Over the years, the Como-based company has confronted the top high fashion brands and the interior design industry by patenting its brands.

Menphis has won the long game. And nothing in this path was taken for granted. The strategic choice was to place departments such as Cratt (Transfer Technology Application Research Center), R&D and Digital Printing at the company’s fulcrum.

“Companies within the company” the founder proudly says; places where technological innovations are tested before their roll-out. The tools of this activity include a passion for surfaces and hi-tech investments. Several milestones have been achieved and all the stages of the journey are presented in the new Showroom, one of the eight buildings where the headquarters are divided within the industrial area of Casnate con Bernate. The sectors of new interest are also represented here, such as the home, relaunching the Chineè (warp printing) and retail where Menphis applies the new transfer technologies.

The advances in innovation have been accompanied by significant investments. For the development of Windye, Menphis invested EUR 2.5 million, mainly on laser systems and tech with a view to 4.0. The new brand has opened new horizons by expanding the surfaces and materials that can be treated (among others wallpaper) and revealing a new dimension for Menphis itself, which evolved as a subcontractor and is now in a position to develop the sales directly through digital channels.

The company has also conquered positions in the field of sustainability with BIOT, presenting eco-sustainable products with 50% bio-based materials. The innovative Windye transfer printing technology on all fibres allows the colours to be fixed in 40 seconds with consequent energy, water and raw material savings.

But what’s more, Menphis has developed technologies for recovering print films. A real circular economy model that allows us to confirm that “we are well advanced on the recycling front”.

The choice to produce in-house inks for printing also paid off. The processing takes place in a dedicated area of one of the factories where the raw material is prepared through a grinding process.

The “powders” department was a winning choice for at least a couple of reasons. This made it possible to reduce costs but above all to expand rapidly in the field of research and development with the possibility of continuously experimenting with the best product for sublimation.

Nowadays, Menphis is an increasingly complex project that associates the production of films and powders with the design and construction of horizontal painting systems and sublimation systems. This step was feasible thanks to the partnership with SEF Italia of Carate Brianza.

Therefore, there are all the prerequisites and basis to continue with MENin PHIlosophy!